Working at height always involves risk. Whether on construction sites, industrial maintenance projects, or exterior building services, falls remain one of the leading causes of serious workplace injuries. Safe rope access systems—including safety harnesses, safety ropes, and energy-absorbing components—form the final and most critical line of defense for workers at elevation.

This guide explains how rope access safety equipment works, how to choose the right system, and how to use it correctly to ensure maximum protection.

1. Safety Harnesses: The Last Line of Defense in Rope Access

A safety harness is designed to secure the worker’s body and distribute fall forces safely in the event of a slip or fall. In rope access operations, selecting the correct harness type is just as important as wearing it properly.

Types of Safety Harnesses:

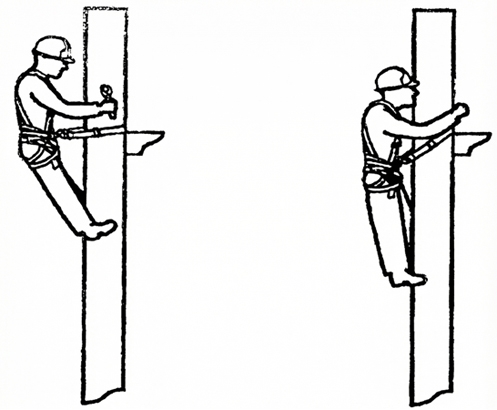

Pole and Structure Work Harnesses

These harnesses are commonly used in electrical maintenance and utility work. By wrapping around fixed structures such as poles or columns, they allow workers to stay securely positioned while keeping both hands free for tools and tasks. This improves stability, efficiency, and overall safety during elevated operations.

Work Positioning and Restraint Harnesses

In construction environments where workers operate on platforms or rooftops, restraint harnesses limit movement and prevent access to fall hazards. Rather than stopping a fall, they are designed to prevent workers from reaching dangerous edges in the first place.

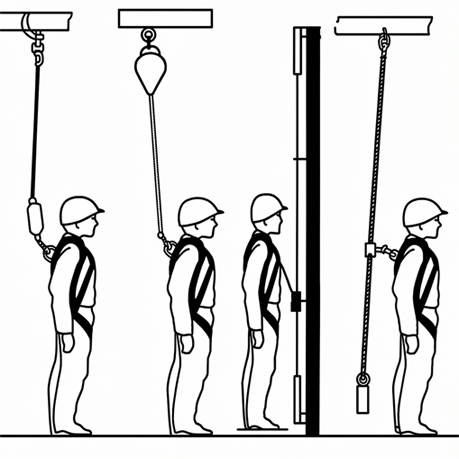

Fall Arrest Harnesses

Fall arrest harnesses are the most widely used solution in safe rope access systems. When a fall occurs, the harness works together with a safety rope and energy absorber to suspend the worker and reduce impact forces. They are essential for activities such as façade cleaning, bridge construction, and high-rise maintenance.

2. Safety Ropes: The Lifeline in Rope Access Systems

A safety rope connects the harness to a secure anchorage point. In rope access work, it plays a critical role in both mobility and fall protection.

2.1 Function and Importance

Safety ropes control movement, limit fall distance, and absorb energy when used with shock absorbers. They allow workers to move within a safe range while ensuring immediate protection in case of sudden loss of balance.

2.2 Common Types of Safety Ropes

Webbing Safety Ropes

Made from high-strength woven materials, these ropes are lightweight and flexible. They are commonly used in general construction, exterior cleaning, and routine maintenance work.

Fiber Rope Safety Lines

Manufactured from advanced synthetic fibers, these ropes provide excellent flexibility and abrasion resistance. They are suitable for rope access tasks requiring frequent movement or positioning adjustments.

Steel Wire Rope Lanyards

Steel wire ropes offer exceptional strength, heat resistance, and durability. They are typically used in heavy-duty environments such as large-scale construction, infrastructure projects, and industrial maintenance.

Chain Safety Lanyards

Chain-based safety ropes are designed for extreme industrial conditions. Their resistance to impact, corrosion, and sharp edges makes them suitable for mining, metallurgy, and high-temperature work areas.

2.3 Key Safety Rope Usage Rules

To maintain effective safe rope access, the following principles must always be observed:

● Never use natural fiber ropes such as hemp; they lack sufficient strength and durability.

● Install an energy absorber when rope length exceeds 3 meters to reduce fall impact forces.

● One rope per person—never allow two workers to share a single safety rope.

● Use double protection in high-risk tasks by combining a harness and a secured safety rope.

● No knots or hooks on the rope, as they weaken structural integrity and increase failure risk.

● Control effective rope length to minimize fall distance and injury potential.

● Do not use safety ropes for lifting or suspension, and never share connectors with hoisting equipment.

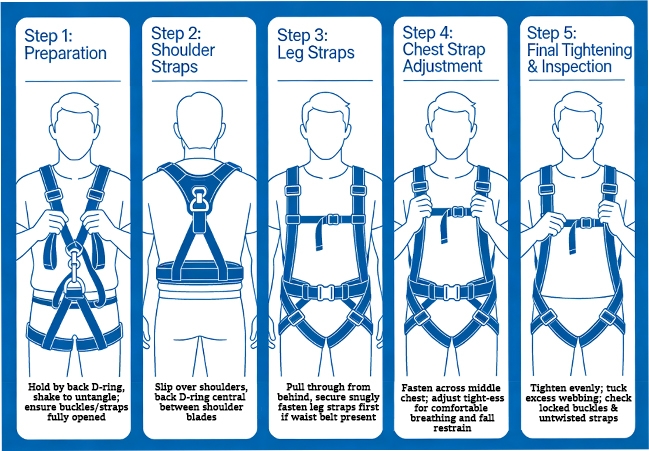

3. How to Properly Wear a Full-Body (Five-Point) Harness

A full-body harness, often called a five-point harness, provides complete fall protection when worn correctly. Small mistakes in fitting can significantly reduce its effectiveness.

3.1 Step-by-Step Wearing Process

1. Preparation

Hold the harness by the back D-ring and shake it out to untangle all straps. Ensure buckles and straps are fully opened.

2. Shoulder Straps

Slip the shoulder straps over your shoulders. The back D-ring should sit centrally between the shoulder blades for optimal load distribution.

3. Leg Straps

Pull each leg strap through from behind and secure it snugly. If a waist belt is present, fasten leg straps first before securing the waist.

4. Chest Strap Adjustment

Fasten the chest strap across the middle of the chest—not too high or too low. Adjust tightness to allow comfortable breathing while ensuring restraint during a fall.

5. Final Tightening and Inspection

Tighten all straps evenly so the harness fits close to the body without restricting movement. Tuck away excess webbing and check that all buckles are locked and straps are untwisted.

4. Safe Rope Access Best Practices and Maintenance

Proper use and care of rope access equipment are essential for long-term safety.

4.1 Storage and Environmental Protection

Store harnesses and safety ropes in dry, well-ventilated areas away from heat, chemicals, and corrosive substances.

4.2 Inspection and Retirement

Always inspect equipment before use. Any signs of wear, burns, chemical damage, stiffness, or metal deformation are grounds for immediate retirement.

4.3 Regular Testing

Safety equipment should undergo periodic inspections and performance testing in accordance with relevant safety standards.

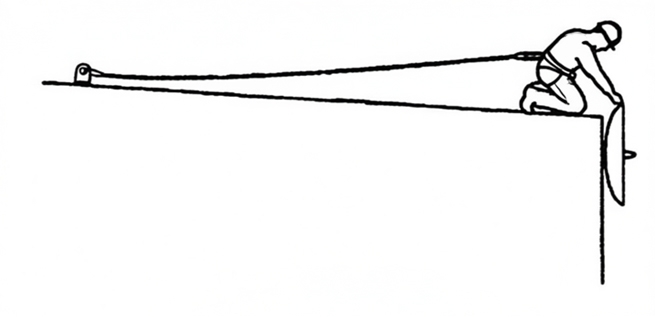

4.4 High Anchor, Low Use Principle

Always attach safety ropes to secure, elevated anchor points. This reduces fall distance and impact forces.

4.5 System Integrity

Never remove or replace harness components arbitrarily. Each part is engineered to function as a complete system.

Conclusion

Safe rope access is not just about having the right equipment—it’s about understanding how each component works together. Proper harness selection, correct safety rope usage, disciplined wearing procedures, and regular inspections collectively form a reliable fall protection system.

By following these principles, workers can significantly reduce risks and ensure that every task performed at height is as safe as possible.