Dropped object netting is a critical safety system used across construction sites to prevent tools, materials, and debris from falling from height. Whether installed around scaffolding, balconies, stair openings, or open edges, compliant netting serves as a protective barrier that reduces the risk of serious injuries and project shutdowns.

I. What Standards Should Dropped Object Netting Meet?

According to updated engineering safety guidelines used in China (2025) and aligned with international site-protection principles, high-quality dropped object netting should meet the following core performance requirements:

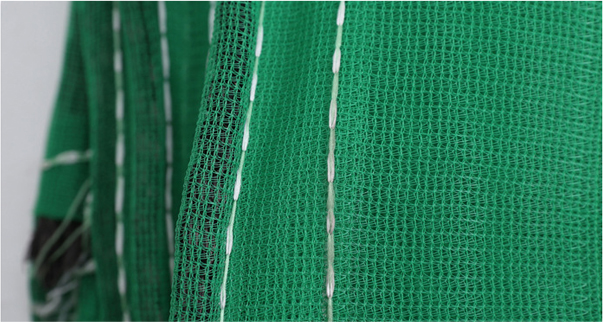

1. High Mesh Density

A dense mesh design helps prevent small tools and materials from slipping through.

Typical requirement: ≥ 2000 mesh/100cm².

2. Strong Impact Resistance

The net should withstand impact from a standard test weight.

Industry benchmark: able to absorb the impact of an 80 kg object dropped from 2 meters.

3. Flame Retardancy

Flame-retardant treatment reduces fire-spread risk on active job sites.

General requirement: self-extinguishing within seconds after flame removal.

These standards ensure the net performs reliably under real construction conditions and reduces secondary hazards.

II. How to Choose Compliant Dropped Object Netting

Choosing the right net is not only about safety—it’s also about meeting inspection requirements and avoiding shutdowns or penalties.

1. Material: Why Ordinary Nylon Is Not Enough

Cheap nylon nets are often made from basic polyester yarns with limited tensile strength. They degrade quickly under UV exposure, may tear under wind load, and rarely include flame-retardant properties.

Recommended materials for construction-grade netting include:

● High-strength polyester

● Modified polypropylene (PP)

● UV-stabilized composite fibers

These materials offer durability, weather resistance, and stable performance over long-term outdoor use.

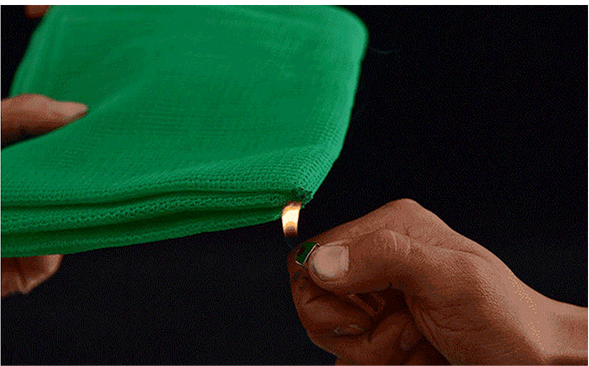

2. Certification: Look for Verified Product Labels

Reliable dropped object netting should carry clear and traceable certifications such as:

● Production license number

● Test report number from a certified laboratory

● Product certificate including manufacturer details and production date

Uncertified netting increases the risk of failure during use and may result in project non-compliance.

III. Installation & Maintenance: The Most Common Job-Site Mistakes

Even the best netting can fail if installed or maintained incorrectly. Below are frequent mistakes found on construction sites—and how to correct them.

1. Incomplete Edge Coverage

● Wrong: Netting only installed on the outer side of scaffolding or leaving openings at corners.

● Correct: Full-height, continuous coverage from the base upward, with special attention to stair turns and balcony edges.

2. Ignoring Cleaning & Damage

● Wrong: Allowing dust buildup or using nets with visible cuts.

● Correct: Inspect monthly, clean regularly, and replace immediately if damage is found. Patch repairs are not recommended.

3. Early Removal

● Wrong: Removing the net once structural work is finished.

● Correct: Netting must remain until dismantling and finishing works are fully complete to prevent accidental falls during final activities.

Creating a daily inspection log managed by the safety supervisor helps ensure accountability and immediate corrective action.

IV. Key FAQs About Dropped Object Netting

1. How often should the netting be replaced?

A full replacement every 6 months is recommended. In areas experiencing heavy rain, strong wind, or UV exposure, earlier replacement may be required.

2. Can the netting be reused?

Yes—but only after each use is inspected. Netting with aging, broken threads, loose buckles, or structural deformation must be discarded. Nets used for more than 2 years should be retired.

3. Do balconies and platforms require netting?

Yes. Modern construction safety rules require all elevated open-edge areas to be equipped with dropped object netting or edge-protection systems to remain compliant.

V. Summary: A Small Investment That Protects Lives

Effective dropped object netting is more than a protective accessory—it is a frontline safety measure that prevents accidents and ensures regulatory compliance. To ensure full protection, remember these three essentials:

● Use high-quality materials (polyester / PP, UV-resistant, flame-retardant)

● Select certified products with verifiable testing

● Install correctly and inspect regularly

A safe site begins with the right netting—and with consistent maintenance to ensure it performs as intended.