Introduction

HDPE shade nets have become a cornerstone material in agriculture, construction, and outdoor engineering. Because they balance strength, UV stability, and ventilation, they outperform most traditional shading fabrics and continue to gain global market share. Whether used above vegetable tunnels, construction scaffolding, backyard pergolas, or industrial storage yards, HDPE nets deliver reliable protection with minimal maintenance.

What follows is a practical, engineer-level overview that helps buyers understand performance indicators, application scenarios, and selection tips based on real-world requirements.

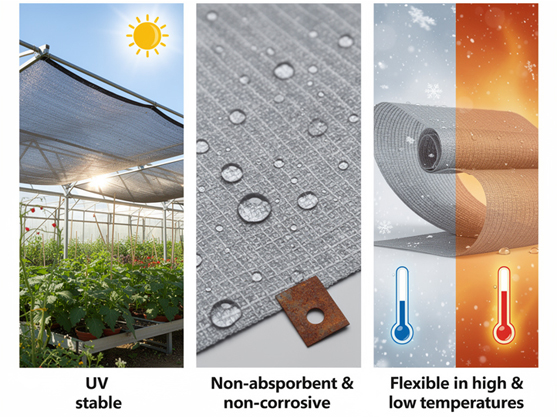

What Makes HDPE Shade Nets Different?

Unlike PVC-coated fabrics or polyester nets, HDPE monofilament yarns offer a high strength-to-weight ratio and remain stable under prolonged sunlight exposure. The material does not absorb water, does not corrode, and remains flexible in both high and low temperatures. These characteristics allow HDPE nets to withstand years of continuous outdoor use—an essential advantage for farms and construction sites.

HDPE shade nets are typically applied in:

● Greenhouses and crop tunnels requiring controlled light and temperature

● Livestock shelters to prevent heat stress

● Construction sites needing dust suppression or temporary shade

● Residential outdoor structures, such as gardens and patios

● Industrial environments where equipment requires protection from heat and UV damage

This versatility comes from a combination of five core performance traits.

Five Performance Traits That Define HDPE Shade Nets

1. Structural Strength Under Extreme Conditions

Well-manufactured HDPE nets can resist high wind pressure—often up to 120 km/h—without tearing. In regions with intense heat or seasonal storms, service life typically ranges from 5 to 8 years, especially when the net has passed ASTM D4355 weathering tests.

2. UV Shielding Efficiency

The addition of UV stabilizers allows HDPE nets to block up to 95% of harmful radiation, slowing fiber aging and preventing brittleness. This is crucial for both plant protection and user safety in outdoor environments.

3. Balanced Airflow and Temperature Control

Unlike solid covers, HDPE nets create a shaded environment while maintaining airflow. Depending on mesh density (30%–90% shade rate), temperatures underneath the net can remain up to 5°C cooler compared with fully covered structures.

4. Resistance to Chemicals and Moisture

HDPE tolerates environments ranging from pH 3 to 11, making it suitable for coastal areas, high-humidity regions, and industrial zones. Anti-mold treatment further stabilizes performance during long rainy seasons.

5. Environmentally Responsible Manufacturing

Modern HDPE nets can be produced using GRS-certified recyclable materials, and many factories comply with ROHS standards to ensure safe and sustainable production.

How HDPE Nets Perform Across Industries

Agriculture

Greenhouses, shade houses, and livestock pens benefit from HDPE nets’ ability to reduce direct sunlight, prevent leaf burn, and lower heat accumulation. Farmers often report fewer crop losses during peak summer and healthier foliage with more even growth.

Construction

On scaffolding or temporary roofing, the nets help control dust, reduce glare, and create cooler work zones. A well-installed HDPE shade layer can reduce cooling-related energy consumption by up to 40%, making it a practical choice for summer construction.

Residential Applications

HDPE nets used for pergolas, pool enclosures, and garden patios can create comfortable 72°F / 22°C shade zones and provide nearly 99% UV blockage, giving homeowners a long-lasting, low-maintenance shade solution.

Industrial Use

Machinery covers and truck tarps made from HDPE netting protect equipment from heat-related wear and extend service life. The material’s resistance to oils and mild chemicals makes it particularly useful in manufacturing plants and logistic yards.

Technical Notes for Buyers

To choose the right net, consider the following specifications:

● Material: UV-treated HDPE monofilament

● Shade Options: 30%, 50%, 70%, 90% (higher shade = lower airflow)

● Color Choices:

● Black — best UV absorption

● Green — visually natural for farms and gardens

● Aluminized — highest heat reflection

● Weight Range: 80–200 gsm depending on durability requirements

● Installation Tip: For slopes steeper than 30°, choose cross-woven nets above 120 gsm to prevent wind uplift and edge distortion.

Why HDPE Shade Nets Remain the Industry Standard

Research from the Journal of Agricultural Engineering (2023) indicates that HDPE nets can last three times longer than PVC alternatives while remaining significantly lighter. Their ability to maintain over 90% light diffusion efficiency makes them ideal for environments where plants need filtered sunlight rather than full shade.

Most internationally traded HDPE shade nets now meet:

● ISO 9001 quality standards

● CE certification for European applications

● USDA approval for organic agriculture environments

When placing orders, buyers usually specify the roll size (e.g., 2m × 50m), required shade percentage, and the preferred edge reinforcement style.